Machine feature

> Newest type CNC turret punch with high speed, more efficiency and lower noise

> Thick turret, better guiding and higher precision, can be longer life-span of tooling

> Rapid loading and unloading tools

> Main parts (turret parts, components of index tool and reducer box, etc) supplied by our company

>the built-in flywheel, crankshaft put in longitudinal, sliding type strike head equipped with imported cluth, the stamping frequency higher, appearance more beautiful.

Product application:

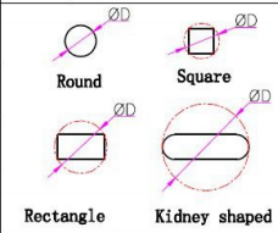

To shape holes, Round, Rectangle, Square, Lover, Stretch Hole, Screen Mesh

The structure of the machine and characteristics

Machine include: Body,Turret,Mechnical system,Transmission system,Stationary worktable,Full floating clamps,Reposition system,The origin of the positioning pin device,Pneumatic and lubrication device,reduction gearbox,Electrical and control system,Tools,Programming Software etc

Feeding in the form of a plate material on the work table movement.

The work table

Nylon brushes table,Table with nylon Brushes allows stainless steel and special surface materials can be processed without damage. The movement of sheet is quiet and smooth.Not be deformation, orientation stability, die wear small

Turret:

Station | Size range ΦD(Max circumcircle) | Standard /normal specifications |

A | 1.6mm~12.7mm

|  |

B | 12.7mm~31.7mm

| |

C | 31.7mm~50.8mm | |

| D | 50.8mm~88.9mm(optional |

| Station | Size | Station | Station | Station |

| 12 | 24 | 32 | ||

| A | 3mm~12.7mm | 6 | 12 | 16 |

| B | 12.7mm~31.7mm | 4 | 8 | 12 |

| C | 31.7mm~50.8mm | 2 | 2 | 2 |

| D | 50.8mm~88.9mm | 2 | 2 |

Clamps:

The originality of using upper and lower floating clamps. The floating clamps make the loading easy, optimizes its working condition and produces big clamping force. In addition, the clamp is of gutter type connection for easy movement.

Mechanical system:

the built-in flywheel, crankshaft put in longitudinal, sliding type strike head equipped with imported cluth, the stamping frequency higher, appearance more beautiful.

Lubricating:

This machine adopts automatic lubrication,equipment under working condition without manual lubrication,The lubricating oil to the lubrication points, reduce the movement friction, improve the service life of the machine, convenient user maintenance work.

Movement structure: The machine movement structure of imported Taiwan HIWIN company is a manufacturer of precision ball linear guide rail,Large guide distance precision ball screws and Japanese NSK company is a manufacturer of precision bearing pairs. High precision, fast speed.

The tooling:

The international universal tooling is of thick turret long guide series, with a high hardness, anti-abrasion ability and good guidance, a long tool life and no shim needed after regrinding. The work range can be expanded with auto indexing stations.

CNC system:

The machine takes the China ADTECH CNC or optional world-famous FANUC or SIEMENS control

system and AC servo system. Features: Universal RS232 standard interface,Chinese and English text are available, mighty diagnostic function, Gripper and punching head auto protection, The international universal G code program. On line data transfer reduces down time and raises productivity.

The machine through the two positioning, can be processed 1250*5000/1250*2500/1500x5000mm sheet

Parameter

Specification | Unit | 1225/1250/1550 |

Transmission mode | / | Mechanical |

Frame structure | / | Open(C type) type |

Punch Force | KN | 250 |

Power Rating | KW | 11 |

Max. Processing Size | mm | 2500*1250 |

Max. sheet Thickness (Iron plate) | mm | ≤4 |

Max. Punch Diameter | mm | Φ50.8(optional Φ88.9)

|

Max. Traversing Speed | m/min | 60 |

Punching Frequency | hpm | 600/900 |

Hole Accuracy | mm | ±0.1 |

Number of stations in turret | No. | 12/24/32 |

Turret Speed | rpm | 30 |

Controlled Axis | No. | 3 |

Air Pressure | mpa | ≥0.8 |

·Voltage | V/HZ | 380V 50Hz 3Phase |

Tooling type | / | Thick turret, long punching tooling |

Worktable structure | / | Brash board |

Outline Dimension | mm | 4850*3300*2100 |

Machine Weight | T | 9 |

0ur Services

Pre-Sales Service

* Inquiry and consulting support.

* Free making samples support.

* View our Factory.

After-Sales Service

* 24 hour technical support by email , telephone or online

video .

*User friendly English manual for machine using and

Maintaining.

*Training how to install the machine,

*Training how to use the machine.

* Engineers available to service machinery overseas.

Two years warranty for the whole machine

Packing and Delivery

Packing:Steel Pallet with Plastic film in Container.

Details:1, machine spares and accessories are packaged into fumigation-free wood box.

2, main body is packaged in water-proof film for anti-rust in shipment.

3, if there is special requirement, all body can be packaged into fumigation-free wooden box. or make wooden pallet.

Quick Details

Condition: New

CNC or Not: CNC

Power Source: Mechanical

Place of Origin: anhui, China (Mainland)

Brand Name: ACCURL

Voltage: 380V, 380V 50Hz 3Phase

Power(W): 11kw

Weight: 9000kg

Dimension(L*W*H): 2.2*2.2*5.1m

Certification: ISO

Warranty: 2 Years

After-sales Service Provided: Engineers available to service machinery overseas

Worktable structure: Brash board

Tooling type: Thick turret, long punching tooling

Air Pressure: ≥0.8mpa

Controlled Axis: 3

Turret Speed: 30rpm

Number of stations in turret: 12

Hole Accuracy: ±0.1mm

Max. Traversing Speed: 60 m/min

Punch Force: 250KN