Delem(2+1 axis) Press Brake with CNC Control System Product Application

This CNC hydraulic press brakes proved the ideal solution for all general bending application.

It uses the proven torsion bar / electro-hydraulic synchronization system, coupled with positive stop nuts in the cylinder to ensure accurate, consistent bends.

Delem(2+1 axis) Press Brake with CNC Control System Product Features

1. Steel-welded construction, vibration to eliminate stress with high strength and good rigidity

2. Double-cylinder synchronous control system, adopt electro-hydraulic servo valve control, with high control accuracy, bending precision. With multiple functions back gauge, control axis optional, Y1, Y2, X, R, Z.

3. The hydraulic system adopts integrated form control system, with less pipeline installation. Adopt import NOK gasket ring, prevent the oil leak, and then improve the working stability accordingly.

4. With mechanical auto compensation worktable, avoid the deformation influence caused by bending processing. The compensation dosage is controlled by CNC system.

5. Italy ATOS valves or American OMG vales optional

6. Electric components SCHNEIDER

7. DZ-UN from Taiwan or Japan NOK sealings for hydraulic system

8. Hydraulic top-drive, steadiness and reliability

9. Electrical hydraulic synchronization, high precision

10. Deflection compensation unit installed on the top die

11. Emergency buttons for back and front control panel, also food pedal

12. Standard top tool & bottom die supplied with the machine

13. Special tools are optional, will be designed according to your needs

14. Cylinder stroke is adjustable, according to your bending needs.

15. Back gauge with servomotor + ball screws + linear guide way.

16. Laser safety protection is optional

17. Standard top & bottom tooling

18. Fast clamping tool

19. Standard front support

20. Delem DA41, DA52, DA69W CNC etc electric controller are to optional.

Our Services

Provide Pre-sales Consultant & On-purchase service 8 hr × 6 days per week

1. Reply within 24 hours

2. Provide relevant product information

3. Answer questions if request

4. Give technical suggestion

Provide After-sales service 24hr × 7days per week

1. Test the machine before shipment

2. Provide technical guidance relate to use the machine

3. Supply one-year warranty period for the machine

4. Provide the spare parts at cost price after warranty period

5. Collect the feedback for the machine working

6. Provide long-term technical assistance.

FAQ For You

Q: What’s the usage for this machine?

---- It is used for sheet metal and nonferrous sheet meal. (4~20mm thickness)

Q: What’s the yield strength for material used for bending?

---- 235Mpa. If you have special request, please point out when make inquiry.

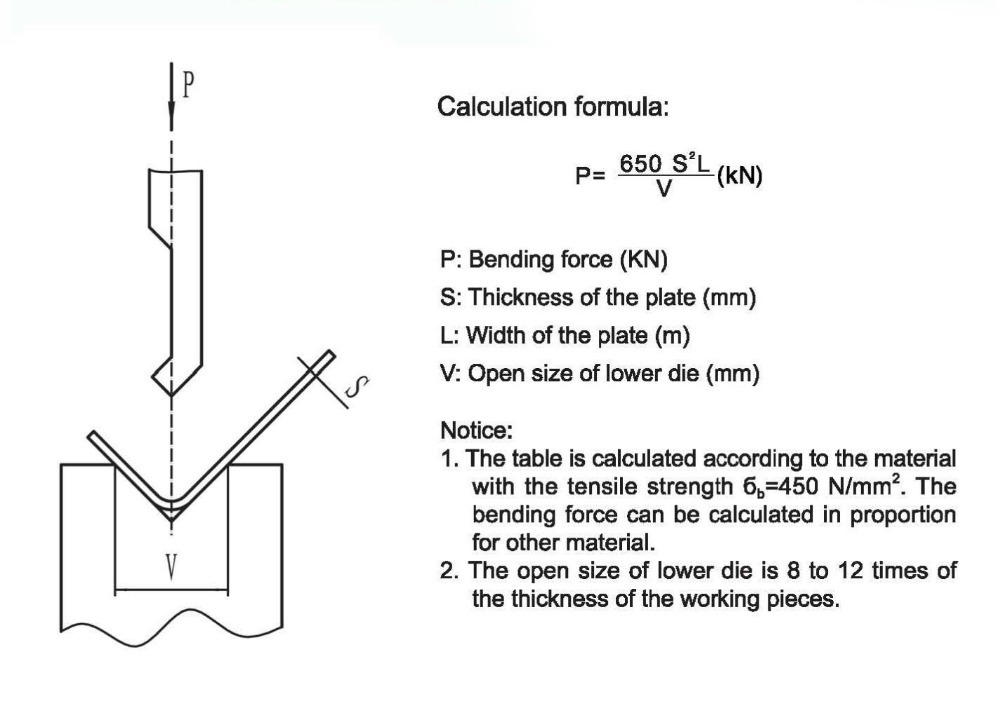

Q: How can I calculate the bending pressure according to material thickness and width?

---- as bellow

Quick Details

Condition: New

Place of Origin: Anhui, China (Mainland)

Brand Name: ACCURL

Model Number: WC67K /WE67K

Machine Type: Press Brake

Raw Material: Steel Bar

Material / Metal Processed: Stainless Steel

Power: Cnc

Automation: Automatic

Extra Services: Machining

Certification: ISO 9001:2000

After-sales Service Provided: Engineers available to service machinery overseas

Name: Delem(2+1 axis) Press Brake with CNC Control System

Color: Blue

Controller standard: E20

Controller optional: E200 / DA41

Electrics: Siemens Germany

Ball screw: Taiwan Hiwin

Connectors: Germany EMB

Grating ruler: Heidenhain Germany