Main Features

1. Totally European design, streamlined looking,Monoblock,Welded steel frame rigid to deflection moment and high tensile with ST44 A1 material.

2. MTR PRESS BRAKE is Equipped with the Estun user-friendly user interface,the E21 provides all main press brake functionality.

3. Automatic tonnage and stroke adjustment for bending angles.Perfect bending results with easy angle input and operation of machine.

4. All tubes are connected by tube insertings to avoid oil lost and burst by welding tubes.

5. Ball screw and line guide was designed to improve precision.

6. E-Z fast wedge clamping was designed to change tools quickly.

7.Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety.

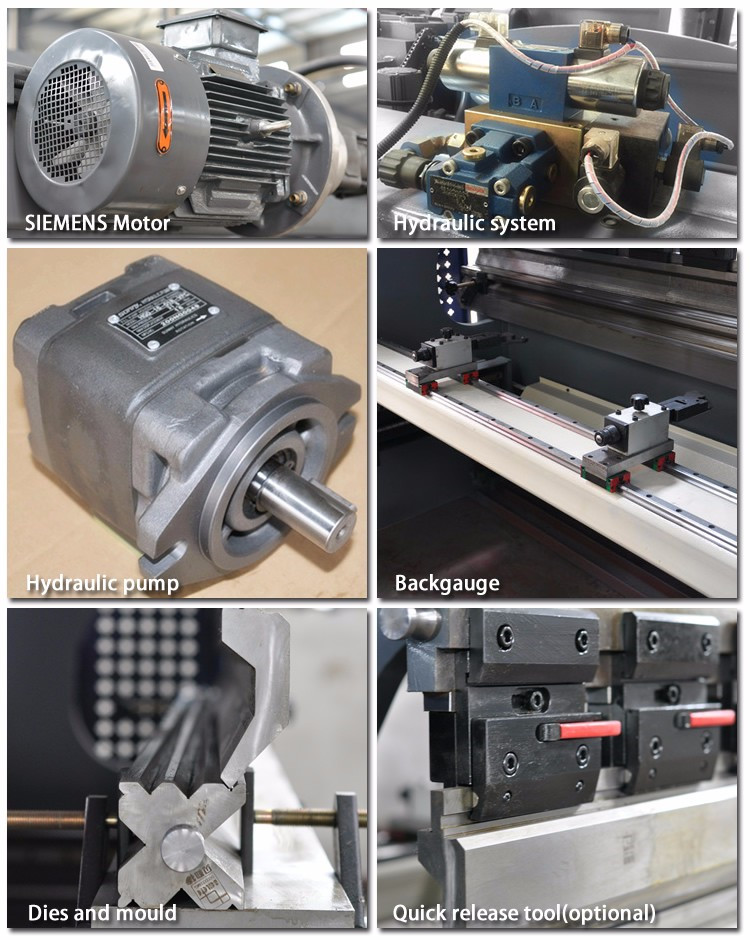

Standard Equipment

1.System Intermediate Upper clamps with Anti Wedges

2.Plate Support Arms

3. Powered Depth Axis

4. Backstop

5. Light guards

6. Top and Bottom Tooling

7. Estun E21 NC control

8. Germany Bosch-Rexroth Hydraulic

9. Telemecanique/SchneiderElectrics

10. Hydraulic and Electrical overload protection

11. Squaring Arm and Front Support Arms

12. Delta inverter with ball screw and polished rod with 0,05 mm accuracy.

13. Side guard is standard meeting CE regulations.

Estun E21s NC Press Brake Control system

1. Monochrome LCD Box Panel.

2. Integral factor programmable freely

3. Automatic positioning control

4.Spindle allowance offset

5.Internal time relay

6.Stock counter

7.Backgauge position display, resolution in 0.01mm

| CE WC67Y Series full servo cnc 4 axis press brake with DA52S control system plate bending machine | ||

| Specification | ||

| Model | ||

Pressure | 630 | kn |

| Lenght of worktable | 3200 | mm |

| Distance between uprights | 2450 | mm |

| Throat Dephts | 250 | mm |

| Stroke | 120 | mm |

| Open Height | 340 | mm |

| Motor power | 5.5 | Kw |

Our Services

1.24 months warranty

2.Spare Parts

3.OEM & ODM are welcome

4.Engineers available to service machinery overseas

FAQ

Q:Are you a factory or trading company?

A: We are a factory.

Q:Where is your factory located? How can I visit there?

A: Our factory is located in Anhui Province(next to Shanghai),China.You can fly to Shanghai airport directly.

All our clients, from home or abroad, are warmly welcome to visit us!

Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end.

Our factory has gained ISO,BV authentication.

Quick Details

Condition: New

Place of Origin: Anhui, China (Mainland)

Brand Name: ACCURL

Model Number: WC67Y-63/3200

Machine Type: Beading Machine

Raw Material: Sheet / Plate Rolling

Material / Metal Processed: Stainless Steel

Power: Hydraulic

Automation: Automatic

Extra Services: End Forming

Certification: ISO9001

After-sales Service Provided: Overseas service center available

Product name: hydraulic plate sheet metal floding bending machine

Pressure: 630KN

Lenght of worktable: 3200mm

Distance between uprights: 2450mm

Stroke: 120mm

Open Height: 340mm

Weight: 6500kg

Warranty: 24 Months

Motor power: 5.5kw

Throat Dephts: 250mm